Types of Leather, Craftsmanship and Care Guide

What is the classification of natural leather?

The skin peeled from an animal's body is called "raw skin" and is a raw material in the leather industry. The art of transforming raw skin, peeled from an animal's body, into usable material forms the foundation of leather crafting. This transformation process, known as tanning, alters the natural leather's properties and appearance to suit diverse applications, from functional to artistic. The type of tanning and subsequent post-processing dictate the leather characteristics, making each piece uniquely suited for various leather art projects. The resulting product, known as leather, emerges as a versatile medium for artists seeking materials that align with their creative vision.

Leather, distinguished from fur, offers superior qualities such as rapid moisture absorption, temperature resilience, insulation, elasticity, and ease of dyeing, making it a preferred choice in leather crafting. Its durability, coupled with the ability to maintain integrity without cracking, allows for endless possibilities in creating lasting works of art. However, the types of leather available carry inherent imperfections, a testament to the natural life of the animal from which they were sourced. Factors such as the animal’s gender, age, and the environment contribute to these variations, ensuring no two leather pieces are identical.

Despite its unparalleled attributes, natural leather requires meticulous care, especially in fluctuating humidity levels, to prevent molding and maintain its esteemed quality. This nuanced balance of benefits and considerations highlights the unique nature of leather, positioning it as both a challenging and rewarding medium for artists and craftsmen alike.

What are the Types and characteristics of natural leather?

Introduction:In order to obtain authoritative leather classifications,exploring the world of leather reveals a rich tapestry of natural leather types, each with its unique characteristics. This chapter delves into the leather classification system, examining various animal leather varieties and the leather grading process, providing a foundational understanding of the diversity and quality standards in the realm of leather.

1、Classification based on animal species

Sheepskin leather properties:Sheepskin is generally divided into goat skin and sheep skin. Cortical features: Sheep skin has fine and dense pores, finer grain size than goat skin, soft texture, greater extensibility, and lower strength. The hair on goat skin is divided into two types: needle hair and down. The pores are slightly thicker than those on sheep skin and cowhide, and thinner than those on pig skin. The cortex is relatively tight. After tanning processing, leather goods with various tactile, strength, color, and pattern can be made, such as backpacks, gloves, leather jackets, and shoes.

Goatskin leather

Sheepskin leather

Cowhide leather characteristics:According to the breed of cattle, cowhide can be divided into yellow cowhide, water buffalo hide, yak hide, etc. Yellow cattle fur has fine pores, fine grain surface, and thin epidermis; Yak skin has several types of fur, including fine needle hair, and coarse hair, with long and dense fur and fine and dense pores; Buffalo has sparse fur, large pores, and a thick epidermis. Cowhide has good breathability and water vapor permeability. The leather surface has a large width, small pores distributed in a circular shape, and the touch feels solid and elastic. The overall feeling is bright and smooth, with a full and delicate texture. When pressed hard on the leather surface, small wrinkles appear. Using cowhide as the substrate, machine processing technology is used to produce leather with crocodile patterns, ostrich patterns, snake patterns, pearl fish patterns, and other patterns; By manual processing, various leather craft products can be made. According to different manufacturing processes, it can be divided into cowhide patent leather, cowhide modified surface leather, cowhide suede leather, cowhide full grain leather, cowhide dual color effect leather, cowhide film leather, etc., As shown in the following figure.

Cowhide leather

Horse skins:Horse skins can be divided into domesticated horses and wild horses. Horse leather has low water permeability and breathability, but high wear resistance, making it difficult to handle. The horse skin is divided into two parts: the front body and the back body, with the boundary line being 3/4 from the head to the back line. The predecessor had a thin thickness and loose fiber weaving; The back is relatively tight. The predecessor of horse leather can be processed into shoe upper leather and clothing leather; The back can be processed into boot upper leather, sole leather, and waterproof shoe upper leather.

Horse skin leather

Raw horseskin

Pigskin:pigs can be divided into artificially raised pigs and wild boars. Pigskin leather has good water permeability and breathability. The pores on the surface of the leather are round and thick, arranged in groups of three in a "pin" shape. Compared to cowhide, pig leather has a lower smoothness and the grain surface is rough when made into shoe upper leather. Due to the dense weaving of fiber bundles, pig leather has high strength and wear resistance. Pig leather is mainly used as accessories, such as lining leather for shoes and bags , and some are also used to make leather clothes.

Pigskin leather

Fish skin:Fish skin can be divided into carp skin, pearl fish skin, grass carp skin, etc. Most fish skins have scales, and after processing, "scale pits" are left on the skin surface, presenting a honeycomb like three-dimensional appearance. Fish leather can be used as decoration and embellishment for bags and leather shoes.

Fish skin leather

Reptile skin:Reptile skin can be divided into crocodile skin , lizard skin, bullfrog skin, and snake skin. The surface of crocodile skin has hard keratin and scales, with obvious protrusions and natural gradient grid patterns. It is suitable for embellishing and matching fashionable leather products, and is often used to make luxury items such as bags, handbags, and wallets. Lizard skin has delicate leather, good breathability and durability, and a fine and textured surface. The snake skin has a thin surface and low strength, with a scaly pattern effect. Due to the scarcity and high price of leather, it is often used as a decoration for luxury bags and shoes, or as a veneer for high-end belts and watch straps.

Crocodile skin

Ostrich skin:Ostrich skin is flexible, resistant to bending, and has much higher strength than cowhide, pigskin, and sheepskin. The pores are high and bulging, like pearls embedded in the leather surface. There is a unique texture like pine needles between the pores, and genuine leather is noble and natural, beyond the reach of imitation ostrich skin. It is often used in luxury goods production.

Ostrich skin

Kangaroo skin:kangaroos are produced in Australia. Kangaroo skin has a smooth grain surface, soft texture, excellent fullness and elasticity, and its appearance can be comparable to cowhide and sheepskin. At the same thickness, kangaroo leather has a tensile strength 10 times greater than cowhide, so it can be made as soft and plump as sheepskin, and is often used in the processing and production of bags.

Kangaroo skin

Deer skin:Deer skin is divided into deer skin and suede. Muntjac is a precious wild animal and is currently a second level protected animal in China. Deer skin is mainly composed of sika deer. Deerskin fur is composed of rough needle hair and short, soft down, which has strong warmth retention. It can be made into sofa covers, clothing, shoes, etc. Its application range is very wide, and it is a precious leather raw material leather .

Deer skin

Deer skin leather

2、According to the classification of leather layers

Raw leather can be divided into top layer leather and second layer leather, where the top layer leather is used to make full grain leather and trimmed leather. Full grain leather refers to the leather that retains and uses the original surface of animal skin (the side with long hair or scales), also known as full grain leather. Smooth leather, also known as matte leather or glossy leather, is made by lightly polishing the leather surface with a polishing machine, then coating it with corresponding patterns. In fact, it is a cosmetic treatment for damaged or rough leather surfaces. Double layer leather is a lower layer of thick leather obtained by slicing it with a leather slicing machine. The double layer leather is made by a series of processes such as coating or film application. Its fastness and wear resistance are poor, making it a relatively inexpensive type of leather in the same category.

3、Classify according to style

It can be divided into smooth leather, lychee grain leather, oil wax leather, water dyed leather, drop grain leather, Napa leather, embossed leather, trimmed leather, patent leather, matte leather, film leather, printed leather, cracked leather, suede leather, etc.

Smooth leather is a leather with the grain layer as the front, also known as full grain leather . The leather surface is required to be smooth and delicate, without wrinkles or loose surfaces, with uniform and consistent colors. The coating layer should adhere firmly, without fading or shedding, and the leather should have no greasy feeling. The color should be bright and beautiful.

Litchi grain leather has litchi grain printed on the surface. All lychee patterns are printed in the later stage of leather processing - whether it is the top layer or the second layer, the natural texture of leather does not have lychee patterns. The appearance of a large number of lychee patterned leather is only because it simulates skin wrinkles. This texture can make finished leather, especially the second layer leather, look more like "skin". The second layer of skin after peeling has no texture, and printing lychee patterns is the best choice; After repairing a large amount of severely damaged scalp, printing lychee patterns is a common technique to cover up the repair marks. However, for the highest quality top layer leather, due to its already beautiful grain effect, lychee patterns are rarely added to the picture.

Litchi grain leather

Lacquer leather refers to a clothing material that is coated with paint on materials such as genuine leather or PU leather, and the surface is processed into a bright and sturdy leather, which has a strong surface effect and style characteristics. Its characteristics are that leather has a bright and natural color, is waterproof and moisture-proof, is not easily deformed, and is easy to clean and maintain.

Lacquer leather products

Distressed leather, also known as oil soaked leather. Smooth texture, pushing the skin by hand will produce a color changing effect. The material mainly consists of top layer cowhide, which belongs to mid to high grade leather.

Distressed leather in D&M leather studio

Nappa leather is made of top layer cowhide and is named NAPPA in English. Napa leather is widely used in industries such as footwear and luggage.

Nappa leather

4、Classification by manufacturing method

After being tanned and processed by a leather factory, animals (skins) are made into materials with various characteristics, strength, feel, color, and pattern, which are essential materials for modern leather products.

The processing of animal skin is very complex, and to make finished leather, it requires dozens of processes: raw leather - soaking in water - removing meat - degreasing - hair removal - soaking in alkali - swelling - dehazing - softening - soaking in acid - tanning - layering - shaving - re tanning - neutralization - dyeing - oiling - filling - drying - finishing - coating - finished leather.

There are many tanning methods for natural leather, such as chrome tanning, aluminum tanning, zirconium tanning, plant tanning, aldehyde tanning, composite tanning, etc. The two most common tanning methods in our daily lives are chrome tanning and vegetable tanning. Plant tanning is the oldest tanning method with a history of thousands of years, and it was also the most important tanning method before the emergence of chrome tanning. The plant tanning method is a process of tanning using pure natural preparations, extracting a mixture of tannins from the cell tissues of plants such as roots, stems, leaves, skins, fruits, and trees, to transform the raw skin into leather. The leather tanned with plant tanning agents has characteristics such as tight tissue, solid and full texture, low elongation, low deformation, good wear resistance, and strong water resistance. Due to the weight of the tanned leather, it is called heavy leather. The plant tanning method has little effect on leather and can be used for post-processing such as shaping, dyeing, and carving. Therefore, leather artists nowadays tend to choose plant tanned leather for their creations. The essential difference between chrome tanning and vegetable tanning is the difference in tanning agents. Chromium tanning is the process of tanning leather using a chemical agent, chrome tanning solution. Chromium tanned leather has the characteristics of high elasticity, softness, and thinness, making it easy for finishing and other processes in the middle and later stages of the tanning process. Due to its lightweight texture, the tanned leather is called light leather and is the most commonly used type of leather in daily life.

According to the grade of leather, it is sorted from high to low as full grain leather, half grain leather, light trimmed leather, and heavy trimmed leather; From the softness to hardness of leather, it is sorted into chrome tanned leather, semi vegetable tanned leather, and whole vegetable tanned leather (tannic leather).

What about Recycled leather and synthetic leather?

Regenerated leather (also known as furs and paper abroad) is made by crushing the waste skins and leather scraps of various animals and blending chemical raw materials. Its surface processing technology is the same as that of genuine leather such as trimmed leather and embossed leather. Its characteristics are that the edges of the leather are relatively neat, the utilization rate is high, and the price is cheap; However, the leather body is generally thick and has poor strength. It is only suitable for making standard process products such as document boxes, pull cases, and ball club sleeves, as well as ordinary belts. The fiber structure in the longitudinal section is uniform and consistent, and the solidification effect of the mixed fibers of the fluid can be recognized. Recycled leather combines the characteristics of genuine leather and PU leather, making it a very common leather material nowadays. Like genuine leather, regenerated leather has moisture absorption and breathability. Well crafted regenerated leather also has the same softness and elasticity as genuine leather, with a light texture, strong resistance to extreme high and low temperatures, and wear resistance. Its disadvantage is that its strength is lower than that of genuine leather of the same thickness, and of course, it is also worse than PU leather, making it unsuitable for leather products with high stress such as shoe uppers.

Artificial leather, also known as imitation leather or rubber, is a general term for artificial materials such as PVC and PU. It is made by foaming or laminating PVC and PU with various formulas on textile or non-woven fabric substrates. It can be processed according to different strength, wear resistance, cold resistance, color, gloss, pattern and other requirements. It has the characteristics of a wide variety of colors, good waterproof performance, neat edges, high utilization rate, and relatively cheap price compared to genuine leather. However, the majority of synthetic leather cannot achieve the same texture and elasticity as genuine leather; Its longitudinal section reveals fine bubble holes, thin films on the fabric or surface, and dry artificial fibers. It is a type of material that has been extremely popular from the early days until now, widely used to make various leather products or partially replace genuine leather materials. Its increasingly advanced production technology is widely adopted in the processing and production of double-layer leather. Nowadays, artificial leather with characteristics resembling genuine leather has been launched on the market. Its surface technology and fiber structure of the base material almost achieve the effect of genuine leather, and its price is also quite reasonable. But genuine leather has unique hygiene (natural pores and fibers) and durability that cannot be compared to imitation leather (regenerated leather and synthetic leather).

What are the dimensions and cutting instructions for leather?

The shape of commonly used leather is irregular, and the measurement standard is usually area, without calculating length or width. Due to differences in the leather body, slight variations in color and fiber length on the back are normal phenomena. Size conversion of leather:

1 square foot=0.0626 square meters. If it is a square, it is approximately 25cm x 25cm. 1ft2=0.0929m2, if it is a square, it is approximately 30cm x 30cm.

Generally, leather is sold by ft2. A whole piece of leather is usually 20-28 ft2, and usually half of it is 10-15 ft2 when purchased. 11ft2 is approximately equal to 1m2. Leather can be cut in different areas according to different parts , including whole leather, half leather, shoulder leather, hip leather, and edge and abdomen leather.

The appearance of leather cut according to 30cm * 30cm

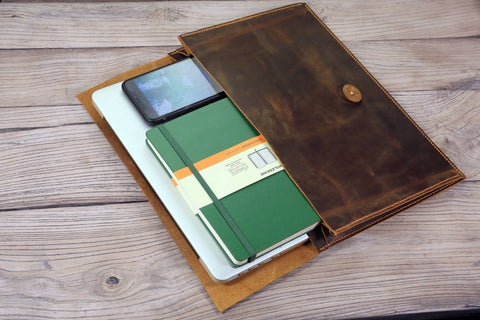

According to the different objects of production, corresponding leather positions will be selected for design and production. At the same time, for the selection of leather thickness, the outer skin of the wallet is usually made of 1.8-3mm thick leather, and the inner layer is usually made of 1-1.2mm thick leather. For small or large bags, 1.6mm, 1.8mm, or 2.0mm or thicker leather is required.

What are the common defects in leather?

Leather's beauty is often marred by unavoidable leather imperfections due to the animal's objective survival status and the leather processing methods. These imperfections can include cracks, spots, scars, holes, and branding marks on the leather surface, making it less pristine compared to the flawless leather goods found in shopping malls. Identifying leather defects is crucial for repairing damaged leather effectively. To prevent leather wear and tear, proper storage is essential. If not in immediate use, leather should be wrapped in cloth or kraft paper and stored flat in a dark, dry, and ventilated area to avoid moisture, mold, and insect damage. Notably, the color of vegetable-tanned leather, favored for carving, will gradually deepen under light exposure, enhancing its aesthetic appeal over time.

Leather back (the lower layer of the leather surface is fibrous, and the texture of different types of leather fibers varies, mostly with a fuzzy texture)

Leather insect spots (Cattle growing in the wild can infect their skin through contact with small insects or parasites, which naturally affects their skin)

Leather pores (scars formed by excessive external force on cows, which will remove larger leather surfaces during the tanning process)

Leather scars (scars caused by external forces on cattle during grazing are inevitable)

Leather texture (the folds of cowhide are more prominent under the shoulder, neck, belly, etc., and natural texture is inevitable)

Blood vessels (there will be lightning like marks on the skin surface where blood vessels pass through, which is the best evidence of genuine leather. When purchasing leather, you can look for such marks to appear)

The wrinkles on the rib skin pattern (these are the wrinkles attached to the rib skin pattern. The most widely used part of cowhide is the rib, but the fiber density varies depending on the distribution position, resulting in wrinkles of various sizes)

Pigment black spots (After dyeing, the dye will accumulate in the small wounds or pores of cowhide, forming the black spots you see. Many people consider them as flaws in the dyeing process, but such spots faithfully present the personality of cowhide and the uniqueness of leather)

Good Evening, I was wondering where you sourced your leather from. I just purchased one of your beautiful Vintage Floral Embossed Leather A5 Journal Binders from Etsy, and am curious as to the origins of the leather.

Thank you very much,

Anna-Maria